Manufacturing to Meet Needs

In order to provide implants for more than 430,000 people over the last 25 years, we have continually refined and expanded our manufacturing equipment and processes.

The first prototype Instruments and Implants were developed by Acumed, a medical device manufacturing company based in Portland, OR. Even when we purchased our first machines, we relied heavily on their staff for programming, training, and advice. Dr. Zirkle’s father, Lewis G. Zirkle, Sr., generously donated funds for the purchase of the machines and to remodel the first shop in 2001.

Production Growth

SIGN Production Shop in 2007

From 2000 to 2003, SIGN Machinists and Engineers purchased and learned to program two Swiss Lathes and two Cincinnati Mills, along with many other machines to accommodate the finishing processes and quality inspections.

In response to the growing demand, in 2007 we expanded into an additional 20,000 square feet in our building and added new machines. Additionally, we reduced costs by moving to a hybrid cell manufacturing layout.

SIGN’s Research and Development Cell increases our ability to innovate products.

In 2020, we expanded again, creating a Research and Development Cell, so that prototype designs would no longer interrupt the flow of production, and expanding the Engineering, Quality Control, and Shipping departments.

We added two screw-making machines in 2021 and refined our processes, dramatically improving product rejection rates and increasing efficiency.

Expanding and Innovating

New to us in 2024, the OKK Horizontal Milling Center is a high-production machine. This has the capacity to double our production of SIGN Nails.

In 2024, we are expanding again, with the purchase of two production machines that will increase production capacity, enable some overnight production, and allow us to create parts that previously had been outsourced.

Today, we have the capacity to produce more than 30,000 SIGN Implants and enough instrument sets to start 25 new SIGN Programs per year. The most recent expansion provides capacity for future growth as needs arise.

True to the culture inspired by Dr. Zirkle, we have continually innovated with our manufacturing processes and capabilities, and will continue to innovate and improve to meet needs into the future.

What is the memory about SIGN that first comes to your mind? Perhaps it’s a patient, meeting with a surgeon, or something else in your life that sparked a connection with fracture care.

We’d love to hear from you, and potentially share your story. Please comment below or email us at info@signfracturecare.org

In honor of SIGN's 25 years of healing, would you consider making a monthly gift of $25 or more?

Check the "Monthly" box and type in your gift amount on the donation form.

Discover more!

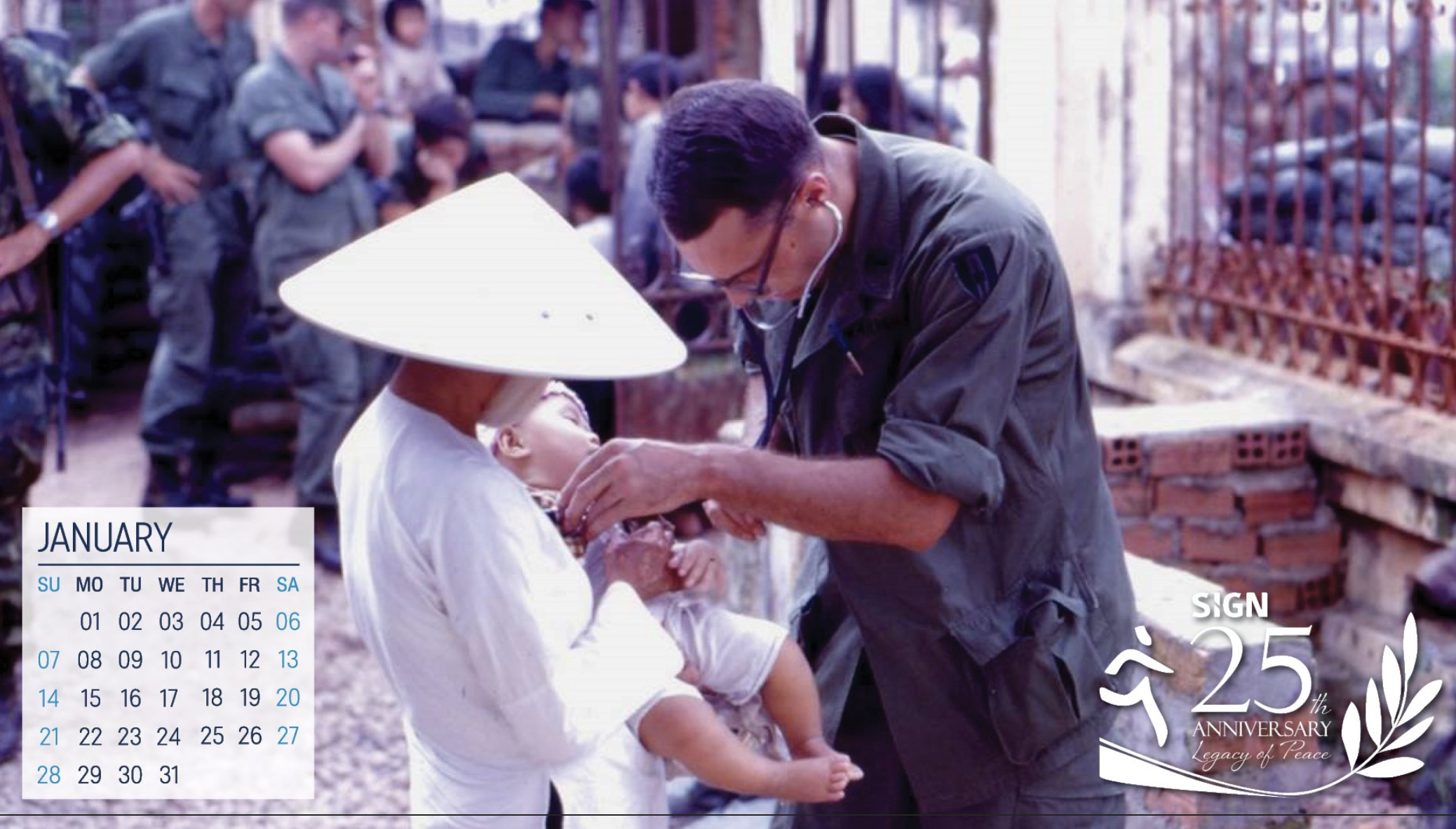

Throughout the year, remember your support of SIGN with background images for your computer or phone.

Discover events that shaped SIGN in a historical timeline.